Designing a Formula SAE Carbon Fiber Electronics Mount

This was a small FSAE project I did towards the end of the design season. The goal was to make a small lightweight shelf to hold most of the electronics in the back of the car. I learned a lot about designing carbon fiber parts as well as the material's limitations.

The purpose of the mounting shelf was to has an easy to access place for the control boards, data loggers, shutdown circuits, and power distribution for F28, one of our first electric cars. I also explored making one large waterproof box for all the electronics but decided it wasn't feasible for this year.

|

| Electronics mounted to the shelf |

The electronics also had to be grounded per the FSAE rules. The carbon wasn't conductive enough to fully ground all the components so I specced out some copper tape to put on the bottom of the shelf to ground the electronics through the bolt holes.

I chose to use generic Hexcel carbon because it was available at the time. I selected a +90/0 direction for the extra strength and rigidity lengthwise along the shelf. I also added a 0.25" aluminum core between the carbon for added strength and rigidity. The bottom corners of the shelf have "hard points", layers of stacked carbon that are much more resistant to compression than the aluminum core.

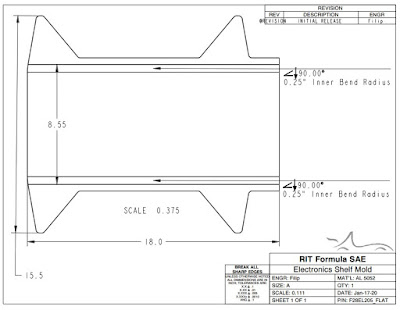

The carbon was layed up on a polished aluminum sheet bent into shape. The mold was a negative mold to keep the outer surface of the shelf smooth.

|

| Layup diagram for the carbon part |

|

| Bending diagram for the mold |

Update: the car is now driving, here's a few pictures of the shelf: